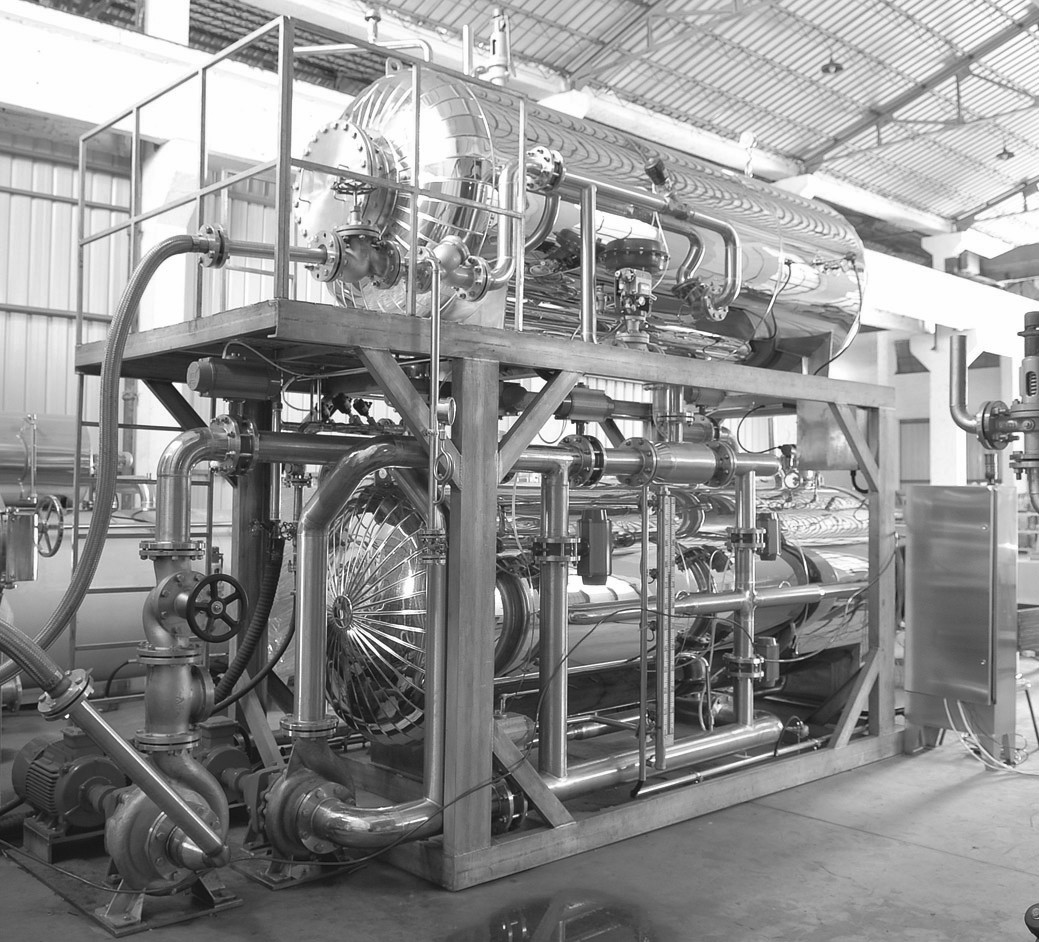

Autoclave sterilizer is a complete equipment unit that uses heat energy to sterilize food and beverage. ZR has been a professional autoclave sterilizer manufacturer and sold the equipment well at home and abroad for decades. ZR supplies commercial autoclave sterilizer in both spray and water bath type, and laboratory autoclave sterilizer featuring the above two sterilization methods. Water bath sterilization method refers that the sterilization water immerses completely the package of the food and beverage to be sterilized, and spray sterilization method refers to spray sterilization water from the top or side of the autoclave to sterilize the package of the food and beverage. Laboratory autoclave sterilizer is usually used for trial and validation of various sterilization processes so that users can select the optimal sterilization scheme before large-scale sterilization operations in their workshop. ZR has standard product lines for commercial and laboratory autoclave sterilizer, and their specific configurations appended at the end of this article.

Here takes laboratory autoclave sterilizer as an example, to introduce ZR autoclave sterilizer in details; Other types of autoclave sterilizer work in a similar way, the main differences are only for their processing capacity and sterilization method.

Working principle of laboratory autoclave sterilizer:

The bottom of the autoclave sterilizer is equipped with a 20L water storage tank, which is used to store softened water as sterilization water and to be recycled. When the sterilization basket is pushed into the autoclave sterilizer and the autoclave door is closed, the sterilization water filtered by the strainer is sucked by the circulating pump, and transferred to the heat exchanger heated by the steam. In top spray mode, heated sterilizing water is sprayed evenly over the treated product from a nozzle located at the top of the sterilizing basket. As the circulating water flow rate is up to 10 m³/hour, the sterilization water inside the autoclave is circulated once about every 7 seconds, thus the temperature inside the autoclave keeps uniform. The PLC of the control system automatically opens and closes the steam valves according to the sterilization water temperature measured by the temperature sensor; and meanwhile calculate the pressure required in the autoclave at this temperature, automatically control the opening and closing of the air inlet and release valve, to ensure that the pressure and temperature match accurately inside the autoclave in the whole sterilization process. When the autoclave sterilizer is in the heating and heat preservation condition, the steam valve and trap automatically open, while cooling water inlet and outlet valve automatically close; When the autoclave sterilizer in the cooling condition, the former automatically closes, the latter automatically opens. When the sterilization process is completed, the circulating pump stops, and the sterilization water returns to the storage tank for the next sterilization operation. All sterilization process is automatically operated by the PLC control system, except for the sterilization basket put in and out by manual.

Advantages and characteristics of laboratory autoclave sterilizer

Design: proper structure, equipment energy consumption is 30% lower than the steam sterilizer, and no steam exhaust process and noise pollution.

Fabrication: plasma automatic weld for autoclave shell, stable and reliable quality.

Material: SS 304.

Appearance: stainless steel mirror plate for insulation part, mechanical polishing for other parts, in line with food hygiene and aesthetic requirements.

Control: water inlet, heating, heat preservation, cooling, drainage and other process full-automatic control, one-button start; Control system is capable to preset 10 kinds of sterilization process, and call immediately; Up to 12 phases of temperature change are capable to be set in each sterilization process; The temperature and back pressure in the autoclave are accurately controlled according to the preset values to ensure the perfect sterilization effect.

Heat distribution measurement: each autoclave sterilizer passed the strict heat distribution measurement before delivery, and temperature measuring error is less than 1.5℃ in heat preservation stage, and pressure measuring error is less than ±0.02Mpa, all to ensure the safety and reliability of sterilization operation by each batch.

Autoclave door safety lock: quick autoclave door is equipped with triple safety locking device, respectively for mechanical manual locking, pressure self-locking and photoelectric positioning locking, to ensure the safety of operators.

Multiple recording methods: automatic temperature and pressure recording, and the printer or (paper or paperless) recorder are for option.

ZR laboratory autoclave sterilizer standard configurations

|

ITEM |

SPECIFICATIONS |

REMARK |

|

|

1 |

equipment model |

ZRSD600A |

spray & water bath |

|

2 |

capacity |

15-30Kg/batch |

subject to product package |

|

3 |

dimensions |

1300×1000×1800mm |

|

|

4 |

weight |

750Kg |

|

|

5 |

autoclave sizes & vol. |

Φ600×450mm,0.12m³ |

|

|

6 |

autoclave shell material |

SS 304 |

thickness 4mm |

|

7 |

temperature measuring error |

<1.5℃ |

heat preservation stage |

|

8 |

temperature rising speed |

<10min. |

30℃-121℃ |

|

9 |

max. pressure allowed |

0.3MPa |

working pressure |

|

10 |

test pressure |

0.5MPa |

shop test pressure |

|

11 |

PLC |

|

Siemens, 1 set |

|

12 |

HMI |

|

Siemens, 1 set |

|

13 |

pressure sensor |

0.4Mpa |

made in Germany, 1 set |

|

14 |

temperature sensor |

PT100 |

made in Germany, 1 set |

|

15 |

steam trap |

G3/4 |

Spirax Sarco, 1 set |

|

16 |

ball valve |

DN25-65 |

made in Germany, 6 sets |

|

17 |

heat exchanger |

2㎡, SS 316L |

plate type |

|

18 |

circulating pump |

10m³/h,head 30m |

|

|

19 |

max. temperature allowed |

142℃ |

|

|

20 |

total power |

4.25KW |

|

|

21 |

steam input |

0.5Mpa, 40Kg/h |

by user |

|

22 |

cooling water input |

0.3-0.4Mpa, 3T/h |

city water, by user |

|

23 |

pressured air input |

0.7Mpa, 18m³/h |

by user |

|

24 |

sterilization basket |

SS 304 |

1 set |

ZR top spray commercial autoclave sterilizer standard configurations

|

# |

ITEM |

SPECIFICATIONS |

REMARK |

|

1 |

equipment model |

ZRSD1200-4 |

spray & water bath |

|

2 |

capacity |

600-1200Kg/batch |

subject to product package |

|

3 |

dimensions |

4700×2400×2500mm |

|

|

4 |

weight |

3600Kg |

|

|

5 |

autoclave sizes & vol. |

Φ1200×3900mm, 4.8m³ |

|

|

6 |

autoclave shell material |

SS 304 |

thickness 4mm |

|

7 |

condensate tank sizes & vol. |

Φ710×1500mm, 0.6m³ |

|

|

8 |

condensate tank shell material |

SS 304 |

|

|

9 |

temperature measuring error |

<1.5℃ |

heat preservation stage |

|

10 |

temperature rising speed |

<12min. |

30℃-121℃ |

|

11 |

max. pressure allowed |

0.3MPa |

working pressure |

|

12 |

test pressure |

0.5MPa |

shop test pressure |

|

13 |

PLC |

|

Siemens, 1 set |

|

14 |

HMI |

10” |

Siemens, 1 set |

|

15 |

pressure sensor |

0.4Mpa |

made in Germany, 1 set |

|

16 |

temperature sensor |

PT100 |

made in Germany, 1 set |

|

17 |

steam trap |

G3/4 |

Spirax Sarco, 1 set |

|

18 |

ball valve |

DN25-65 |

made in Germany, 8 sets |

|

19 |

heat exchanger |

16㎡, SS 316L |

plate type |

|

20 |

circulating pump |

200m³/h, SS 304 |

|

|

21 |

max. temperature allowed |

142℃ |

|

|

22 |

total power |

11KW |

|

|

23 |

steam input |

0.5Mpa, 1000Kg/h |

by user |

|

24 |

cooling water input |

0.3-0.4Mpa, 30T/h |

city water, by user |

|

25 |

pressured air input |

0.7Mpa, 18m³/h |

by user |

|

26 |

sterilization basket |

SS 304 |

4 set |

|

27 |

cart for basket |

SS 304 |

4 set |

Note: The configuration is subject to change without notice. this article can’t include all models and specifications, welcome to inquire for further information.